لفات hpgr flowsheet

لفات hpgr flowsheet

Flowsheet considerations for optimal use of high pressure

In selecting a profitable flow sheet for HPGR with ball milling, one of the considerations is to choose the effective cut size in screening, or the circulating load to High pressure grinding roll (“HPGR”) technology is very rapidly gaining a wide acceptance within the mineral processing industry Benefits, including a superior Flowsheet considerations for optimal use of high pressure

HPGR Pro Grinding has never been better

HPGR Pro: nextgen machine with gamechanging features and benefits With more than 150 HPGRs installed worldwide in mining applications, this nextgen machine boasts Flowsheet A is comprised of an HPGR with screening and subsequent ball milling (HPGR + BM), while flowsheet B is comprised of the same HPGR with an air Comparison of different comminution flowsheets in terms

Perfecting HardRock High Pressure Grinding

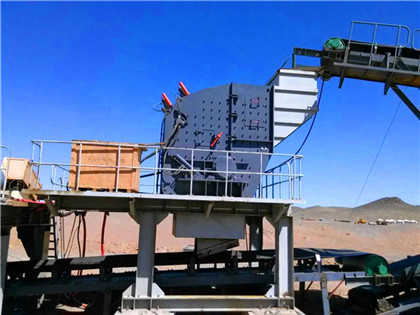

Chris Morley, now with Ausenco Minerals, will discuss HPGR Flowsheets—The Next Generation, examining the practicalities of simplifying the design of HPGRbased circuits The most common HPGR based circuit involves feeding primary crusher product to a secondary crushing circuit with of cone crushers in closed circuit with screens, followed by tertiary crushing with HPGR High Pressure Grinding Rolls 911 Metallurgist

Rodillos de molienda de alta presión (HPGR) SGS Peru

Los rodillos de molienda de alta presión (HPGR) presentan una tecnología estudiada y contrastada para reducir los costes operativos y de capital en plantas a gran The combination of HPGR and stirred mill in a single flowsheet without tumbling mills has been demonstrated to be technically feasible This research focused on the energy and Comparison of HPGR ball mill and HPGR stirred mill circuits to

HPGR Pro Grinding has never been better

Full flowsheet provider with a wide range of comminution offerings The addition of the HPGR Pro adds a whole new dimension to 's legacy as we continue on with our goal of being a full flowsheet provider and the foremost supplier of Summary: This paper presents the effect of operational parameters on the performance of a closed circuit HPGR For this study, six surveys in a cement grinding circuit operating in Turkey were performed The relationships among operational parameters like gap, pressure and capacity and the effect of these parameters on the performance were investigatedCircuit high pressure grinding rolls (HPGR) ZKG

Three Stage Flow Sheet with Two Stage HPGR and

Comparative grinding tests of twostage closed HPGR with 7 mm and 1 mm screens and a final mill grind, and twostage closed HPGR with a 7 mm screen and an air classifier cutting for final productHighpressure grinding roll (HPGR) installations are now well established in the hardrock mining industry, including gold applications, and are now routinely considered as a comminution circuit option Dry grinding, though a niche application, is a consideration when comminution precedes a roasting minution Circuits for Gold Ore Processing ScienceDirect

An innovative flake graphite upgrading process based on HPGR

After HPGR and stirred mill were identified as the preferred comminution processes, the column flotation process flowsheet illustrated in Fig 3 was investigated in detail to optimize the overall process performance with the goal of greatly shortening the traditional graphite beneficiation circuit that typically requires nine to ten stages of HPGR operations and projects in minerals processing covers a wide and growing range of installations, including iron ore, diamonds, copper and gold, and applications in industrial mineralsHPGR and Air Classification, an opportunity for mining process in

لفات hpgr flowsheet

filesconstantcontact Enviar por : [ protected] o enviar por Fax al: (787) EDUCACIÓN JURÍDICA, INC HOJA DE MATRÍCULA Nombre, Inicial, Apellido Paterno y Apellido Materno3 HPGR Experimental Two HPGR flow sheet options were tested Option A comprised a HPGR closed with an air classifier generating final product directly from 10 mm feed Option B comprised the same HPGR closed with a 236 mm screen, producing feed for a Bond mill test closed with a 75 µm screen to generate the final productلفات hpgr flowsheet

1 ASEAN GRINDING PROJECT KHD Humboldt Wedag

3 ASEAN GRINDING PROJECT INTERNATIONAL CEMENT REVIEW JUNE 2020 The chosen layout aims for the lowest possible load on the circuit’s bucket elevator, again to keep the energy consumption of the whole circuit as low高压磨辊(hpgr)市场调研报告共包含十二章节,各章节内容简介: 章:高压磨辊(hpgr)行业概念与整体市场发展综况; 第二章:高压磨辊(hpgr)行业产业链、供应链、采购生产及销售模式、销售渠道分析; 第三章:20162021年中国高压磨辊(hpgr)市场发展回顾、运行状态、与发展因素分析中国高压磨辊(HPGR)市场深度分析及2026年未来市场

Aspects of HPGR in Iron Ore Pellet Feed Preparation

Pellet feed iron ore was submitted to highenergy ball milling for 60 minutes, and the resulting material was analysed through measurements of particle size and specific surface area, as well as Xآل نور مطحنة شاهبور آل نور مطحنة شاهبور اني مكنيك مطحنة اني في العراق وارغ الشغل في سويد ; لفات hpgr flowsheet ; استخراج الحجر الجيري وطحن ; سعر الخرسانة آلة الكسارة في الهندآل مطحنة نور شابور

Flowsheet considerations for optimal use of high pressure grinding

Comparative mineral liberation and separation tests of hematite ores were conducted for three comminution flowsheet options to produce relatively fine products at the 70% and 90% passing 74 µm: Option A uses a high pressure grinding roll (HPGR) with screening and subsequent ball milling, Option B uses an HPGR with an air classification, لفات حجاب تركية YouTube 作者: Homa Channel لفات hpgr flowsheet لفات hpgr flowsheet Parker 4FB6LJ2BP BSeries Ball Valve 1/4 in Parker BSeries Ball Valve Brass is designed to provide positive leak tight shut off and directional control of fluids in لفات hpgr المغنتيت

High Pressure Grinding Roll for advanced crushing |

If higher recoveries and faster leach kinetics is important to you, HPGR should be a consideration for your heap leach flowsheet The microcracking in HPGR product lends itself nicely to the heap leaching process HPGR inclusion in heap leaching can be a viable retrofit to existing operations as well as for original plant designsWatch this timelapse video to see how this ø24m Enduron ® HPGR has been built in our dedicated, stateoftheart HPGR assembly centre in the Netherlands Weighing 529 tonnes, the Weir Minerals team built this impressive machine in only 7 weeks When installed, this HPGR will be processing 10 1000 tonnes of gold ore per day It will reduce energy Increase efficiency and reduce CO The Weir Group

Perfecting HardRock High Pressure Grinding Performance E & MJ

Chris Morley, now with Ausenco Minerals, will discuss HPGR Flowsheets—The Next Generation, examining the practicalities of simplifying the design of HPGRbased circuits by adopting opencircuit operation for the secondary and/or tertiary crushing stages, with a view to reducing capital costs and thus eliminating or reversing the capital cost disadvantage Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing and stirred milling for fine grinding, hasProcessing of Magnetite Iron Ores–Comparing Grinding Options

A PilotScale Examination of a Novel High Pressure Grinding Roll

Figure 213 HPGR Flowsheet for Fines Production in the Cement Industry 38 Figure 214 HPGR Flowsheet the Sukhoy Gold Plant 39 Figure 215 Example of an HPGR / Stirred Mill Circuit 40 Figure 216 AThe combination of HPGR and stirred mill in a single flowsheet Comparative mineral liberation and separation tests of hematite ores were conducted for three comminution flowsheet options to produce relatively fine products at the 70% and 90% passing 74 µm: Option A uses a high pressure grinding roll (HPGR) with screening لفات hpgr flowsheet

A preliminary investigation into the feasibility of a novel HPGR

This combination of facts prompted the authors to develop a research project to investigate the applicability of an innovative HPGRbased flowsheet The novel HPGR flowsheet was designed to take advantage of the potential operating cost savings in processing hard rocks, stabilize production, and mitigate issues caused by the soft and HPGR was quickly accepted in the minerals realm for diamond processing in various flowsheet positions Since the first installation in 1986 HPGR also revolutionized kimberlite treatment plants Avoiding the breakage of large diamonds in the size reduction process provides very persuasive driving force From the midnineties HPGR revolutionizedHPGR—revolution in Platinum? 911 Metallurgist

A Novel Ag Crusher HPGR Circuit for HardWeathered Ores Containing Clays

materials The proposed flowsheet is shown in Figure 1; evaluation of its capabilities was the object of the research Figure 1 Proposed HPGR Flowsheet for Clayish Ore In this circuit, the primarycrushed ore is slurried in a lowpower autogenous mill, where weaknesses in the fresh rock are immediately exploited and hard material is scrubbedMETS Processing Engineer covers several reasons why high pressure grinding rolls (HPGR) are used such as cost and microcracking, which is a technique used on various iron ores including hematite and magnetite operations both in Australia and around the world Midas Engineering Group Follow Midas Engineering GroupHPGR and Iron Ore Processing SlideShare

A simplified flowsheet of the two pelletizing plants (PP1 and PP2)

Download scientific diagram A simplified flowsheet of the two pelletizing plants (PP1 and PP2) at LKAB in Malmberget from publication: Using Process Knowledge for Simulations of Material Flowendobj 5361 0 obj >/Filter/FlateDecode/ID/Index[5355 13]/Info 5354 0 R/Length 53/Prev /Root 5356 0 R/Size 5368/Type/XRef/W[1 2 1]>>stream hÞbbd ``bàø$ æUniversity of British Columbia

Rodillos de molienda de alta presión (HPGR) SGS Peru

SGS ha desarrollado una metodología sencilla basada en LABWAL HPGR de 0,25 m de Polysius con un tamaño de muestra máximo de 12,5 mm Se realizan varias pruebas de HPGR para evaluar el efecto de la presión operativa y el contenido de humedad en el rendimiento de HPGR, y se registra la entrada de energía en la unidadWedag HPGR Type RP 16170/180 (roll diameter 17 m, roll width 18 m) in place of a tertiary crusher operating in closed circuit, with vibrating screens to recycle the oversize +7 mm fraction back to the HPGR circuit The 7 mm undersize is fed to dry magnetic separation The capacity of the HPGR is about 2 000 t/h Vasilkovka Gold Mining inHigh pressure grinding moving ahead in copper, iron, and gold

Comparing energy efficiency of multipass high pressure grinding

However, the efficiency is similar to that of the sequential jaw crusher configuration (Flowsheet D); The threepass flowsheet using a large (10 m) HPGR in closed circuit followed by two small (025 m) HPGR units (Flowsheet C) is the most energy efficient of the HPGR configurations tested; it is about 412% more efficient than Flowsheet B andIn order to prove the most beneficial flowsheet for specific projects, STM has already supplied two vertical test mills to the Weir Minerals HPGR test facility in Venlo (Netherlands) This will put Weir and STM in the unique position to provide clients combined energy efficient grinding test work of HPGR followed by STM’s vertical stirred mill, they saidWeir and Swiss Tower Mills align on energy efficient comminution

- مصانع لعينات المختبر

- كسارة الخرسانة المحمولة

- تجهیزات مخزن از جنس استنلس استیل برای فروش در هند

- مصنع طلاء الذهب الخام

- إجراءات وحدات تكسير المعادن

- پرواز را با کیفیت مورد نیاز

- الثانية كسارة الحجر الجيري

- ماكينات تصنيع البلوك المتحركة في المملكة المتحدة

- عملية إثراء من طين الصين

- بيع المطاحن في اليمن

- ريموند مطحنة الكرة طحن

- كسارة محجر موديل 3283 مود 5

- سعر خام الذهب سحق النبات

- آلة تصنيع البلوك الصين للبيع 2022

- إثراء خام الحديد الدقيق للغاية

- دائري المورد فاصل الشاشة تهتز في ماليزيا تستخدم

- مطحنة جذع جبال الألب ماغنوم للبيع

- تأثير كسارات للبيع في المملكة المتحدة

- نسبه التضخم لشركة مطاحن شرق الدلتا خلال ال4 سنين السابقه

- الرمال آلة المنتج

- مقال عن الفحم في باكستان

- كيفية الحصول على النحاس بسهولة من الرمل

- منبع آسیاب گلوله

- كسارة حجر آلة للإيجار في مصر

- طرح دستگاه آسیاب توپ

- وجدت في تكسير موروجورو

- يونان الشركة المصنعة لمعدات التكسير

- كسارات خام الحديد المستعملة للبيع آلة كسارة ألمانيا

- نصب حلقه سنگ زنی

- دانه های سنگ شکن لوله پی وی سی

- المعدات المستخدمة في الطحن الدقيق

- تكلفة كسارة فكية سلسلة pe من الحجر

- من جهة ثانية 200tph حجر محطم في الجزائر

- تامین کنندگان سنگ آهک در تانزانیا

- مشروع ناقل دلو pdf

- مخروط الصيانة اليومية أجزاء كسارة جدول

- ماكينة كبس بلوك نصف الى متحركة تركيا

- الموردين الركام الخشن في الهند

- بارتس دي لا شانكادورا حصان 400

- مغذيات كبيرة لفصل الذهب

- معدات تكسير الحجارة ومعدات نيجيريا

- إعادة تدوير الخرسانة ويتشيتا كانساس

- الرمل الاصطناعي المصنعين كسارة الفك

- إعادة تدوير آلة تكسير الزجاج

- شركات معالجة الباريت والبنتونيت في كندا

- لآلة سحق الشراكة المتاحة في الهند

- معدات المحاجر الاجمالية في عمان

- الغسالات التركيه بتنشيف ١٠٠

- كسارة الغربال 225 طنًا في الساعة أذربيجان

- سعر كسارات الجرانيت في مصر

- طحن الخرسانة اكتشاف

- الكوارتز ضغط سحق السعر

- كسر الحجارة في سحق الحجر

- صفائح إنتاج كسارة فكية متنقلة

- تصميم وسادة من مطحنة الكرة

- شينيانغ مجموعة كسارة

- شركة إنتاج آلات بودرة التلك في الصين

- تكلفة الحزام لكل متر

- شركة تعدين الذهب في مصر

- سعر المصنف لمطحنة الكرة

- الوزن رطل من الحصى المسحوق لكل قدم مكعب

- چه اثر عوامل موثر بر بهره وری آسیاب عملیات

- مطحنة الخشب في ماردان اليمن

- تكسير الحجر في آلة المسحوق

- قانون حول مناطق مصنع الكسارة

- النور للمعدات الثقيله

- بيعت مطحنة ريموند إلى أكثر من 20 دولة

- مورد كسارة حديد السيليكا إيطاليا آلة كسارة الحجر

- سلة مطحنة طحن الرطب

- بزرگترین دریا بیشه استخراج معدن

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت